A Comprehensive Overview to Galvo Motors and Their Effect On Laser Equipments

Galvo electric motors have actually become a crucial element in the development of laser systems, offering boosted accuracy and performance across different applications. These gadgets promote fast positioning of optical aspects, which is necessary for jobs varying from intricate inscription to complicated medical procedures (Galvo Scanner). As innovation advances, the assimilation of closed-loop control systems and synthetic intelligence promises to press the borders of what these electric motors can accomplish. Nevertheless, the implications of these growths extend past plain performance improvements, questioning concerning future applications and market changes. What might this indicate for the landscape of laser modern technology?

What Are Galvo Motors?

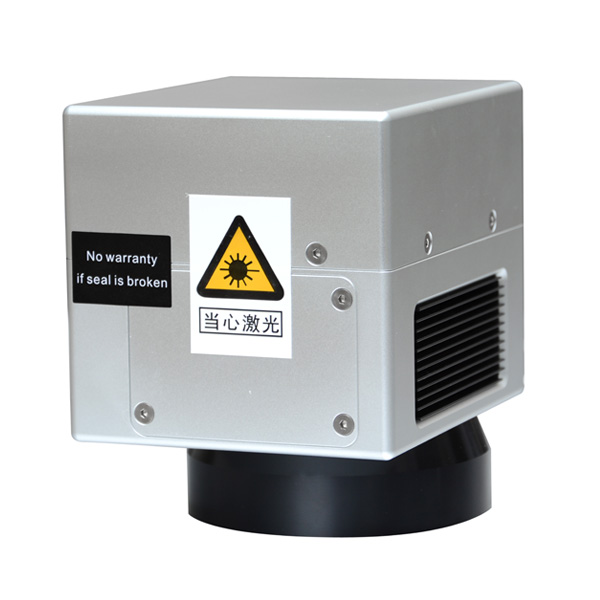

Galvo motors, short for galvanometer electric motors, are accuracy devices used to manage the placement of mirrors or lenses in laser systems. These motors are important to various applications, including laser inscription, reducing, and projection systems, where precise placing is crucial for ideal efficiency. Galvo electric motors utilize a lightweight style that makes it possible for rapid movement, enabling high-speed procedure and accurate control of laser beams.

In addition, galvo motors can be incorporated with sophisticated control systems, permitting advanced shows and automation. This versatility not just improves functional efficiency however also makes sure consistency in outcome. Therefore, galvo motors have actually come to be a crucial part in modern laser modern technology, helping with innovations in various fields by making it possible for precise control of light with extraordinary speed and accuracy.

Just How Galvo Motors Operate

The operation of galvo motors relies upon specific electro-magnetic mechanisms that facilitate rapid and precise positioning of mirrors or lenses. At the core of a galvo electric motor system are rotating coils placed on a shaft, which interact with electromagnetic fields produced by long-term magnets. When an electric current is put on the coils, it develops an electro-magnetic pressure that creates the shaft to revolve. This turning is typically very fast, allowing for real-time adjustments to the angle of the mirrors or lenses.

Galvo electric motors are defined by their closed-loop control systems, which use feedback from placement sensing units to make sure precision. These sensors check the angular placement of the mirrors, communicating data to the controller that readjusts the existing supplied to the electric motor. This responses loop allows for fine-tuning of the electric motor's position, causing high repeatability and precision.

In addition, the lightweight building of galvo motors decreases inertia, allowing quick feedback times crucial for laser scanning applications. Generally, the combination of electro-magnetic principles and closed-loop responses systems allows galvo motors to execute elaborate jobs with phenomenal precision and rate, making them important in advanced laser modern technologies.

Benefits of Galvo Motors

One of the vital benefits of making use of galvo motors in laser systems is their capacity to accomplish accurate and quick positioning, which is important for applications such as laser engraving, cutting, and scanning. This accuracy is mostly as a result of the high-speed reaction of galvo motors, enabling them to swiftly adjust the angle of the laser beam of light with minimal delay.

An additional substantial advantage is their reduced inertia contrasted to conventional stepper electric motors, which enables for quicker acceleration and slowdown. This particular not just enhances the overall rate of laser operations but additionally adds to the quality of the ended up product by minimizing movement blur.

Applications in Laser Equipments

Applications of galvo motors in laser systems extend a broad array of markets, showcasing their versatility and efficiency. Primarily used in laser inscribing and marking, galvo motors make it possible for accurate control over the laser light beam's position, assisting in intricate styles on numerous materials such as metals, plastics, and glass. Their quick response times and accuracy dramatically enhance production efficiency, making them indispensable in producing procedures.

In the world of laser cutting, galvo motors permit high-speed operations, minimizing the moment required for elaborate cuts while preserving side quality. This capability is especially helpful in fields like automobile and aerospace, where precision is essential. Galvo motors are important in laser scanning applications, such as in 3D laser scanning and imaging systems, where they help with fast data purchase and evaluation.

Clinical applications likewise take advantage of galvo innovation, especially in laser surgical procedure and analysis tools, where precise beam control is paramount for effective end results. On top of that, the appearance of laser-based micro-machining procedures has seen the adoption of galvo electric motors, improving the capacity to carry out fragile operations with unrivaled precision. Generally, galvo electric motors play a crucial role in progressing laser modern technology throughout varied areas.

Future Patterns in Galvo Technology

Increasingly, advancements in galvo modern technology are positioned to revolutionize numerous fields that depend on laser systems. One considerable trend is the integration of fabricated intelligence (AI) and device learning formulas into galvo control systems. These technologies boost accuracy and adaptability, enabling real-time modifications based on vibrant environmental problems or material residential properties.

One more arising pattern is the development of higher-speed galvo electric motors, which help with faster handling times in applications such as laser engraving and cutting - Galvo. As sectors demand quicker turn-around times, these technologies will come to be necessary for keeping affordable advantage

Additionally, miniaturization of galvo components is making laser systems a lot more versatile and compact. This trend is particularly appropriate in industries Galvo such as medical devices, where area constraints are vital.

Verdict

Galvo motors have arised as a critical element in the evolution of laser systems, offering boosted precision and efficiency throughout different applications.Galvo motors, short for galvanometer electric motors, are precision devices used to regulate the placement of mirrors or lenses in laser systems. Largely utilized in laser marking and etching, galvo electric motors enable specific control over the laser beam's placement, assisting in intricate styles on various materials such as metals, plastics, and glass. Galvo electric motors are important in laser scanning applications, such as in 3D laser scanning and imaging systems, where they promote rapid information procurement and analysis.

As improvements in closed-loop control systems and artificial intelligence combination proceed to evolve, the capacity for galvo electric motors to better transform laser systems stays considerable, encouraging increased speed and minimized activity blur, thereby expanding their utility throughout varied commercial fields.

Comments on “Understanding Galvo and Its Function in Laser Marking and Inscription Systems”